- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

Answers

- 0

- 0

What are Nickel Alloys Used For?

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Oil futures tumbled more than $5 a barrel on news that the Biden administration is considering releasing about 1 million barrels a day from the U.S. Strategic Petroleum Reserve (SPR) for several months to cool surging crude prices.

Brent crude futures were down $4.71, or 4.2 percent, at $108.58 a barrel by 0035 GMT. U.S. West Texas Intermediate futures fell $5.45, or 5 percent, to $102.74 a barrel.

At an earlier time, gasoline prices had already reached record levels because of the Russia-Ukraine conflict.

The prices of other commodities like the nickel alloy are also expected to be volatile.

Nickel alloys are metals made by combining nickel as the main element with another material (usually titanium, copper, aluminum, iron, and chromium).

It combines two materials to provide more desirable functions, such as higher strength or corrosion resistance. Due to its unique performance, it is used in a variety of devices in multiple industries.

About 90% of all new nickel sold each year is used to make alloys. The most popular is stainless steel, which accounts for about two-thirds of newly produced nickel alloys.

Enhanced properties provided by the material:

Improved versatility

Higher toughness

Enhanced corrosion resistance

Oxidation resistance

Strength increases at higher and lower temperatures

Magnetic

Electronic properties

Many nickel-based alloys have excellent properties at temperatures above 1000°C, making them ideal for extremely harsh environments. They provide excellent oxidation resistance at high temperatures while maintaining high-quality weldability, machinability, and ductility.

How long is the life of nickel alloy?

Nickel alloys have an average life of 25 to 35 years. Depending on the application, the service life may be longer. So, the material is more cost-effective than other metals. Nickel alloys are recyclable and have one of the highest recovery rates in the world. About half of the nickel in stainless steel products comes from recycled nickel materials.

Nickel alloy applications:

This material is common in a variety of devices and objects that people use every day, including:

Mobile phone

Food preparation equipment

Medical equipment

Laboratory equipment

Transportation

Plane

Pharmaceuticals

Building materials

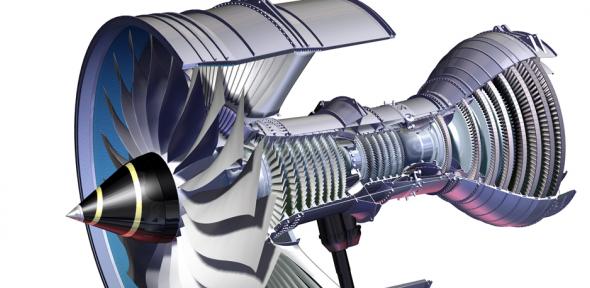

Aircraft and power turbines

Nuclear power system

The energy, chemical, petrochemical, and power industries rely on nickel superalloys for their excellent oxidation resistance and high-temperature strength in critical applications. Alloys of nickel, chromium, and molybdenum offer enhanced corrosion resistance.

Superalloys are made by adding homogeneous elements (including chromium, aluminum, cobalt, and titanium) to produce optimal directional solidification or single crystal structure, thus giving the material strength beyond that of ordinary steel. These nickel-based alloys are used in extremely hot environments, such as gas turbines and aircraft for electricity generation.

Iron-bearing nickel alloys are popular in electronics and specialty engineering. Nickel alloys with copper are used in Marine engineering because of their corrosion resistance in seawater.

Wastewater treatment and piping systems have increased the use of this type of stainless steel because of its very low corrosion rate when treating water, even at high flow rates. It also offers incredible strength and ductility and is easy to manufacture, making it easier to use a cheaper method of joining when assembling pipes.

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and Nanomaterials, including metal alloy, nitride powder, graphite powder, zinc sulfide, calcium nitride, 3D printing powder, etc.

If you are looking for high-quality metal alloy at a very good price, please feel free to contact us and send an inquiry. ([email protected])

The resurgence of the global COVID-19 pandemic and the impact of the Russia-Ukraine conflict continued to cause high volatility in commodity prices. Stubbornly high inflation and rising commodity prices are likely to influence each other and thus push each other higher. The price of the nickel alloy may not decrease significantly in the short term.

Inquiry us

PREVIOUS NEWS