- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

News

- 1

- 1

Micro heat sink: a tiny miracle at the forefront of technology

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

With the rapid development of technology, electronic devices are constantly moving towards miniaturization, and heat dissipation has gradually become a focus of attention. Microheat sinks, as a key technology to solve this problem, are gradually receiving attention from the industry. A micro heat sink is a small and specially designed heat dissipation device for microdevices.

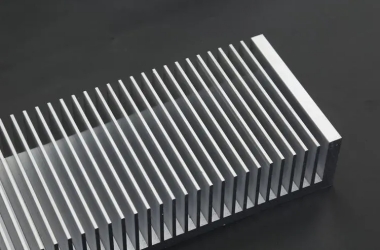

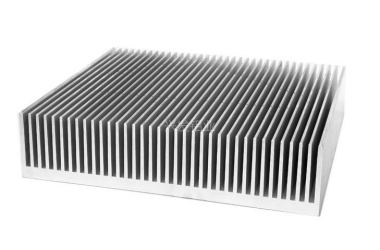

(heat sink)

The characteristics of micro heat sink

Compact size: Compared to traditional heat sinks, micro heat sinks have a smaller volume and are more suitable for devices with limited space.

Efficient heat dissipation: Micro heat sinks effectively achieve efficient heat conduction and dissipation by utilizing advanced heat dissipation technology and materials.

High integration: Easy to integrate with microdevices without additional space, achieving a good heat dissipation effect.

Application fields of the micro heat sink

Microelectronics: With the rapid development of microelectronics technology, the integration of chips is becoming increasingly high, and micro heat sinks provide an ideal solution to solve the heat dissipation problem of chips.

IoT devices: There are a large number of IoT devices, and they are often located in complex environments. Microheat sinks can provide stable and efficient heat dissipation services for them.

Aerospace field: Aerospace equipment has extremely strict requirements for weight and volume, and micro heat sinks precisely meet their lightweight and efficient heat dissipation needs.

(heat sink)

Advantages and disadvantages of micro heat sink

Advantages:

Compact size: significantly reduces space occupation, making device design more compact.

Efficient heat dissipation: By utilizing advanced technology, micro heat sinks can quickly conduct heat and dissipate heat.

Low cost: Micro radiators have lower manufacturing costs than traditional radiators.

Disadvantages:

Limited scope of application: mainly suitable for miniaturized and highly integrated devices.

Technical challenges: Due to volume limitations and technological complexity, research and production are challenging.

How to improve the performance of micro heat sinks.

New material research and development: Explore new materials to improve thermal conductivity efficiency.

Optimize structural design: By improving the structure of the radiator, the heat dissipation area and airflow efficiency can be increased.

Intelligent control: By integrating sensors and control systems, the micro heat sink can operate intelligently and its heat dissipation performance can be further improved.

(heat sink)

Supplier

PDDN Photoelectron Technology Co., Ltd. is a high-tech enterprise focusing on the manufacturing, R&D and sales of power semiconductor devices. Since its establishment, the company has been committed to providing high-quality, high-performance semiconductor products to customers worldwide to meet the needs of the evolving power electronics industry.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality HEATSINKS, please send us inquiries; we will help you.

Inquiry us