- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

News

- 0

- 0

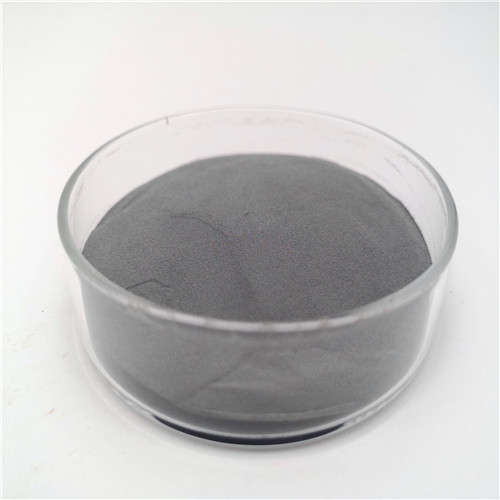

Properties of Nickel-based Super Alloys

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Gold is a high-quality hedge hedging tool, favored by investors. Especially in recent years, with the increasing instability of the world economy, gold has become one of the preferred asset allocations of investors because of its functions of hedging and fighting inflation.

Earlier, the worsening situation in Ukraine sent gold prices soaring to a two-year high of $2,070 an ounce. But gold, along with other commodities, fell back last week as conditions changed and bulls took profits, hitting a low of $1,895 an ounce. As of press time, gold was trading at $1,918 an ounce, down 7.9% from its March 8 peak. Rising gold prices may also have an impact on the Nickel-based Super Alloys prices.

According to China Business News, Goldman Sachs raised its gold price forecast in early March, considering Asian buyers' gold consumption demand, investment demand and central bank gold purchase demand continue to rise. Three -, six - and 12-month targets were raised to $2,300, $2,500 and $2,500 an ounce, respectively, from $1,950, $2,050 and $2,150. The last time all three accelerated was in 2010-11 when gold prices rose nearly 70%.

The World Gold Council has also noted that global gold demand is at its highest level in nearly two years, which is linked to a recovery in consumption and consumer sentiment to combat inflation.

The creep rupture strength can be a good indication that the creep rupture life/γ-initial fraction diagram of each alloy series is different, but each series may have a maximum value or exceed 75% (volume) in the vicinity. This means that the creep rupture life depends partly on the hardening of the solid solution and partly on the hardening of the γ-prime precipitation. When Cr in γ'is replaced by W and Ta, the maximum solid solution hardening will be achieved. In addition, in order to obtain maximum precipitation hardening, a gamma prime fraction will be obtained. In some Ni-based superalloys, the γ-primary fraction of the actual alloy at 1000ºC may be less than the design value.

Tensile properties The tensile properties of sample solutions aged under various conditions at 900ºC have been observed. Obviously, these changes can be well approximated by the linear function of the gamma prime fraction. The results obtained from other series of alloys show that the linearity is maintained in the range of γ-prime fraction of 50% to 80% (volume), which is different from the case of creep rupture strength. The effect of solution temperature is also linear. A higher solution temperature gives a higher yield strength. The lower the solution temperature, the greater the tensile elongation, but this trend no longer works below a certain temperature. The solution treatment below 1080ºC has no beneficial effect on the tensile elongation. For the effect of solid solution hardening and precipitation hardening, it is obvious that W is the most effective method of solid solution hardening, and Ta (a γ-primer forming agent) is less effective than W as a solid solution hardening element.

Heat-resistant corrosion

The crucible test was used to evaluate the resistance to corrosion resistance. A piece of alloy (diameter 6-8 mm, height 3-5 mm) in a salt mixture (Na2SO4-25%NaCl) was kept in the air at 900ºC for 20 hours. After all the scale is removed, the resistance is quantitatively determined by the metal loss. In terms of morphology, thermal corrosion can be divided into three types. Type I: Corrosion layer composed of Cr sulfide, Ni sulfide and porous oxide, Type II: Thin and compact Cr2O3 corrosion layer, there is a small amount of sulfide or no sulfide in the matrix, Type III: It is oxidized by three layers Corrosion layer composed of Cr2O3, TiO2 and Al2O3 from the outside to the inside, a small amount of chromium-rich sulfide is dispersed in the matrix. Regression analysis was carried out on 42 alloys that produced Type I corrosion. The results show that Hf-doped alloys with high Cr and Ti content (the most preferred in γ-primary precipitation hardening alloys), and the addition of W, Ta or Mo is an essential element to increase high-temperature strength. Extremely harmful to thermal corrosion.

About KMPASS

KMPASS is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality chemicals and Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa, Tanzania, Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a leading nanotechnology development manufacturer, KMPASS dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for In718 powder, please send an email to: sales2@nanotrun.com

Russia is a major supplier of industrial metals such as nickel, aluminium and palladium. Russia and Ukraine are both major wheat exporters, and Russia and Belarus produce large amounts of potash, an input to fertiliser. The price and market of the Nickel-based Super Alloys will fluctuate under its influence. Prices of these goods have been rising since 2022 and are now likely to rise further because of the Russia-Ukraine conflict. Russia is a major supplier of industrial metals such as nickel, aluminium and palladium. Russia and Ukraine are both major wheat exporters, and Russia and Belarus produce large amounts of potash, an input to fertiliser. The price and market of the Nickel-based Super Alloys will fluctuate under its influence. Prices of these goods have been rising since 2022 and are now likely to rise further because of the Russia-Ukraine conflict.

Inquiry us